The Beauty and Durability of Painted Cedar Siding

Introduction to Painted Wood Siding

What is the appeal of painted wood siding with so many look-alike products available today? Wood lovers know you can’t duplicate the look of real wood. It adds value and curb appeal to your home.

Painting cedar siding offers the most protection against UV, moisture, and airborne debris such as dust, dirt, salt, and sand.

Advantages of Painted Cedar Wood Siding

Paint is a film-forming finish that can mask the natural grain, texture, and color of wood. While you lose wood’s natural beauty, you gain a virtually unlimited palette of color choices. Painted cedar siding has a long wear expectancy – up to twenty years depending on the environment.

Maintenance Tips for Painted Siding

A good cleaning and inspection once a year is always recommended for painted wood siding. New wood or bare wood must have a primer coat before painting.

Understanding Paint Grade Wood

What is paint grade wood?

Not all woods are created equal. Wood is either hardwood (slow growing, dense, loses leaves yearly) or softwood (fast growing, light weight, evergreen). Wood can be considered exotic, like Brazilian Ipe, Tiger Wood and Garapa. There are inexpensive woods, such as pine, spruce and fir. And, popular premium woods like cedar and redwood.

For those wondering can you paint cedar siding, it's important to know about the wood types. Wood is either hardwood or softwood, with softwoods like cedar being ideal for painting cedar wood siding due to their ability to accept paint finish well and hold up over time.

For this article we’re talking about woods most widely used for wall siding, both exterior and interior. Do they accept paint finish well and hold up over time?

Choosing the Right Wood for Painting

What does “paint grade wood” mean to you?

"I just need a paint grade wood"

We get calls every week with someone requesting “…the least expensive wood you offer because I’ll be painting it”. And, “I need paint grade wood” or “We’re painting it so it doesn’t need to be the good stuff”.

People request paint-grade wood thinking a less expensive wood is fine because they’re going to be painting it. That is absolutely NOT the case.

Not all woods are suitable for painting, especially for outdoor applications like siding. Cedar is highlighted as a premium choice for painted cedar siding before and after transformations due to its natural resistance to elements and lack of pitch, unlike some other softwoods.

Knots and painted wood siding

You have to be very careful with what type of wood you decide to paint. Knots will show through some paints and indications of knots are apparent in most painted applications. Bleed-through is an ugly truth for a lot of softwoods; how much or how little depends on the wood species.

The wrong wood can be disastrous under paint. Ponderosa pine, for instance, will bleed pitch through the knots which causes major problems under paint.

Cedar and redwood don’t have pitch – that sticky substance exuded through the knots of most inexpensive softwoods.

Painted Wood Siding Application

Consider the application for the painted wood, as well. Wood species you’d use inside your home may not be as suitable for exterior wall siding. While paint is an extremely effective protection against UV and moisture it can’t extend the life of inexpensive wood to acceptable long-life performance comparable to cedar or redwood.

Buffalo Lumber specializes in exterior wood siding applications. We know siding investment can be substantial and the wood needs to perform for many years. You have to take long term performance into consideration as well as upfront costs.

Best Wood Options For Painting – Exterior Siding Application

In the wood siding business, you can't afford to quote options that will not work out for the customers, long term. Our customers need to be as happy 15 and 20 years down the road as when they purchased the wood.

Nobody’s happy if the paint doesn’t hold up or the wood rots off the walls in 5 years.

You can always find someone out there who will prime knotty pine for you and let you use it at your own risk. However, we would not quote that option as we know it is a recipe for disaster.

Painted wood options for exterior siding will be limited if quality that equates to durability and longevity is a factor in your selection, which it should be. When we offer painted wood siding options to our customers, we really only see one wood species choice for exterior siding. Cedar.

Best Practices for Painted Cedar Siding

Painted Cedar Siding Exterior Application

When considering painting cedar siding, it's crucial to choose the right wood species. Cedar and redwood stand out for their durability and suitability for exterior wall siding, providing long-term performance and aesthetics.

Cedar – Clear Finger-Joint or Solid Plank:

- Cedar is extremely durable, lasting upwards of 50 years.

- It is rot and insect resistant.

- Cedar is resin free and holds up beautifully under paint.

Unless we are talking about a barn siding or “rustic look” customer who does not mind seeing knots under the paint, most customers aren’t happy with that look.

They want a smooth, clean finish on a traditional or contemporary home. Our cedar options satisfy most customers’ aesthetic style.

Clear Finger-Joint Painted Cedar Siding

The finger joint is a seamless wood connection made by cutting a set of interlocking rectangular “fingers” into the end of two pieces of wood, which are then glued together. The finger-joint is the most common joint used to form long pieces of lumber from solid boards.

There are advantages to Clear Finger-Joint Cedar:

- Clear grade (virtually no knots) at a very economical price point, as compared to Clear Grade Solid Plank Cedar.

- Long board lengths – 16 and 20 footers – that can be harder to get in Solid Plank Cedar.

- Clear Finger-Joint Cedar offers the same high level of durability and longevity as Solid Plank Cedar.

As soon as I say "finger-joint" everyone has the same reaction. "It will come undone – I’ve heard horror stories about telescoping where the fingers swell and rise above the board surface."

I’ve heard those same stories. However, we have NOT experienced this.

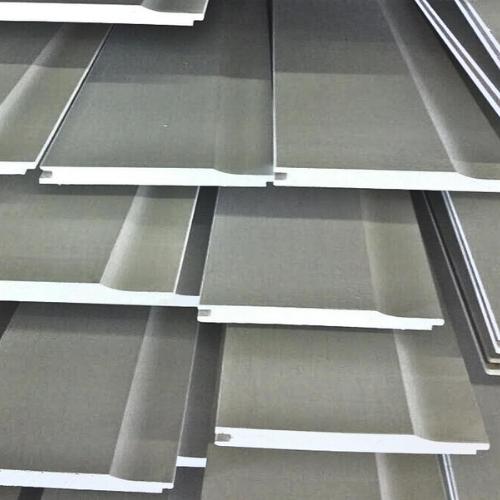

Look at the image above left. The new milling technology of finger-joint is more akin to tongue and groove joinery – where each "finger" fits into a groove between the board edges.

They don’t show up under primer and no telescoping. The top seams are straight. The image above right is old-style joinery on the top of the board.

The finger joining process has evolved, as have the polymers that go into glue formulas. This wood product is specifically designed to be primed and painted to look beautiful and perform for years, as referenced in the WWPA HRA & Finger-Jointed Lumber pdf.

Structural Finger-Jointed lumber products are graded using the same rules and design values applied to solid-sawn dimension lumber. Because it is typically fabricated from wood seasoned below 19% moisture content structural glued lumber is exceptionally dimensionally stable, as referenced in WWPA TG9 Structural Glued Lumber.

Here is an example of a respected manufacturer's Finger Joint Cedar performance warranty.

"... Finger-Joint Wood Products will be free from manufacturing defects which cause rot, corrosion, delamination or excessive swelling from moisture for a period of fifty (50) years from the date of purchase".

That means they cover the finger-joint cedar substrate for 50 years!

Between our supplying mills and our own sales, we have had great results with this product and I feel confident in prescribing it as a long-term performance option. When you need clear grade and you’re planning to paint your wood siding, Clear Finger-Joint Cedar is the best choice!

Clear Finger-Joint Cedar can be milled in a variety of popular patterns, i.e., Bevel, Shiplap-Square Edge, Shiplap-Nickel Gap, Channel Lap, Dutch Lap, T&G-Flush Joint and T&G-Shadow Gap, T&G-Drop Edge.

In our experience, the best results are achieved with factory applied primer plus one paint topcoat, then apply a final paint coat in the field, to blend the whole painted wood siding result together. This is how you get a 25-year warranty and this is how you achieve peace of mind.

Solid Plank Cedar Painted Wood Siding

Solid Plank Cedar is another excellent choice for painting cedar wood siding. Painted Solid Plank Cedar is an ever-popular siding option, available in knotty to clear grades.

Mill Select Cedar Solid Planks are a Select Tight Knot (STK) grade, budget-friendly and beautiful, especially if you’re looking for a bit of natural wood character in your siding. Once primed and painted knots will not be an overwhelming factor in the finished look.

This Mulberry Green solid stain (as opaque as paint) is one factory coat and one final coat on-site. Finished and installed, the knots are not a factor in the over-all appearance.

The factory finish “barn red” paint, over a bleed-blocking primer, received a final top coat on-site. Again, the knots aren’t an outstanding feature in the final appearance. Even up close the knots blend with the natural wood character and add a touch of rustic charm.

Clear Grade Cedar Solid Planks are the hardest to get and the most expensive of the grade choices. Why would you paint this gorgeous, expensive wood?

Not many do. Historic building committees often request it because painted clear grade wood was the cladding of choice on many historic buildings.

Factory Pre-Finished Painted Cedar Siding

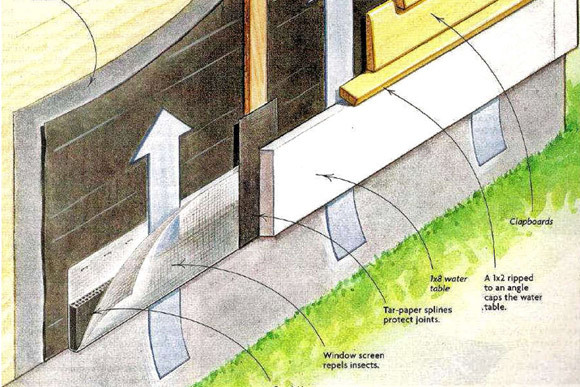

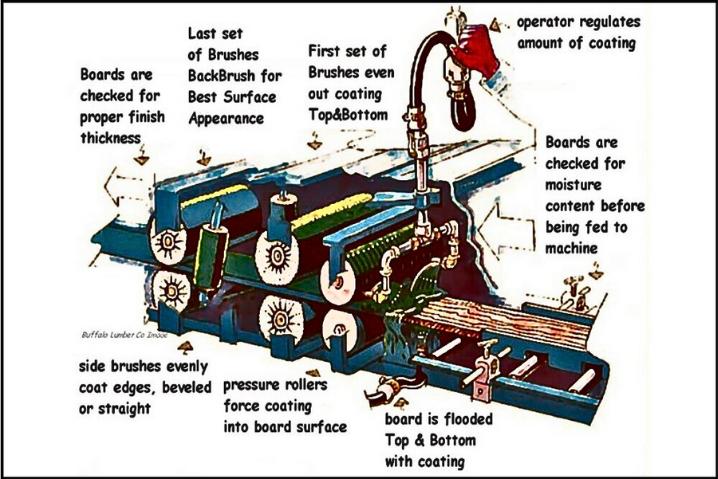

Whether your choice is Finger-Joint or Solid Plank, factory pre-finishing is discussed as a superior method for preparing cedar siding for painting and has several advantages.

- The pre-finish machine applies the all-important back seal as it simultaneously coats the board face, as well as the top and bottom edges with primer.

- The paint coat is applied to the face and top/bottom edges. The butt and cut ends are touched-up on-site. In tandem with Gap-Install Technology, will help ensure your siding’s maximum durability and longevity.

- Factory pre-finishing eliminates the problems of lap marks, shrink lines, streaking, color variation, and job site dirt pick-up.

- And, best of all, factory pre-finishing costs about half the amount of on-site finishing.

The best results will be achieved with a factory applied primer plus one paint topcoat and a final paint coat in the field. This gives you a finish that will last many, many years.

Cedar tannins could cause minor bleed-through. We always utilize a high-quality bleed-blocking primer and paint to mitigate any cedar-bleed issues.

If you’ve purchased paint, you know there is a wide range of prices. More expensive paints generally have better quality ingredients and a higher dry-film thickness that can make a difference in long-term durability. You can control how much of the wood’s character you see by choosing a second or third paint coat on-site. Each coat covers more wood grain and will produce a more uniform, less rustic appearance.

Look at that bad boy … Gnarly!!

Best Wood Options For Painting – Interior Applications

Our preference for an economical wood for interior walls and ceilings is SPF. SPF stands for Spruce, Pine, Fir. They are considered one species, growing in the same cluster of trees, and similar enough that all three are mixed into one product line.

We use SPF for our Painted Wood Paneling line. SPF is a white wood. It’s lightweight, easy to work with, takes paint well, and generally has small tight knots.

SPF is available in several grades.

- Select Tight Knot (STK) limits the size and type of knot but no limit on how many knots. We use the highest visual grade of STK, referred to as J-Grade.

- Near Clear has very few, very small knots at a slightly higher price point, suggested if the aesthetic is a high-end, refined look.

SPF for Painted Wood Paneling works for all interior styles, e.g., rustic, cottage, boho, shabby sheik, traditional, or contemporary.

Bleed-through can be an issue with SPF. The pitch and sap bleeds from the knots, through the paint, showing as an ugly yellow/brown discoloration. Certain pines have a lot of knots. We source only SPF J Grade STK and Near Clear Grade. Combined with our factory pre-finish, using a high-quality bleed-blocking primer, bleed-through problems are greatly diminished.

For best results we suggest a factory finish, with our bleed-blocking primer, applied to the face and back of boards, as well as top and bottom edges. We also suggest one paint coat at the factory, applied to the exposed face and top/bottom edges.

The Painted Paneling is ready for installation. You’re done if you like a touch of rustic charm with some natural wood character. You can apply a second paint coat on-site for a more uniform look. Each paint coat masks more of the wood’s character.

In Our Experience

Wood lovers know the value of real wood and Painted Wood Siding has maintained its popularity for decades.

If your exterior siding project is screaming budget friendly painted wood and you –

- need clear grade, Clear Finger-Joint Cedar is the way to go.

- want a bit of rustic charm, Mill Select Cedar Solid Planks fits the bill.

Both Painted Clear Finger-Joint Cedar and Painted Solid Plank Cedar offer the highest durability and longevity levels found in any softwood.

Properly primed, painted and installed, the finish can last 20 years, depending on environment. And, cedar siding will stand the test of time, performing 40, 50, 60 years with proper maintenance.

Source SPF for Interior Painted Paneling. Its light color and tight knot or near clear grade have the highest visual impact and the lowest bleed-through issues.

Factory pre-finish is the best option for exterior and interior wall siding and is more economical than on-site finishing.

We address bleed-through possibilities by always using a high-quality bleed-blocking primer.

Finger-Joint Cedar, Knotty Cedar Solid Planks, and Interior SPF are the only affordable options in painted wood siding that we recommend because we know you can't risk even the slightest chance of failure. These painted wood siding options have performed in the past and continue to prove themselves today.

Remember, the cost of doing things right is measured in perspective. It costs 10 times as much to fix something done incorrectly than to do it right in the first place. 100% of the people who have done it right feel it was worth it in the end.

This is the truth as we know it.

Good luck out there, Wood Lovers!